Brief of Product

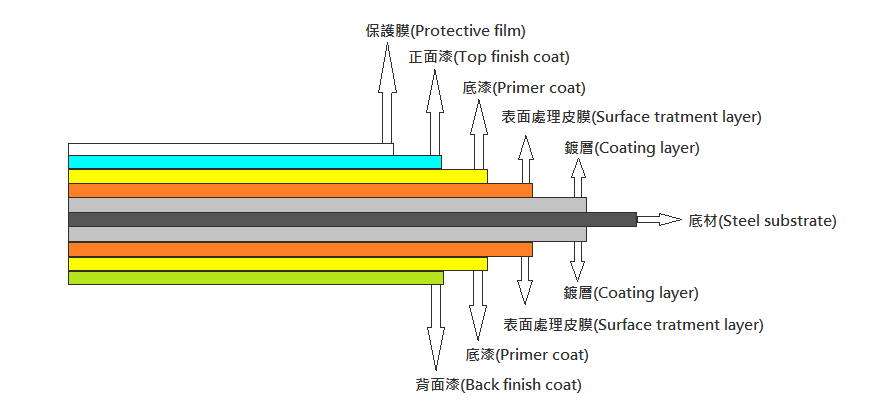

In order to keep coating layer from contacting air directly, protecting steel substrate from rusting and increase coating layer corrosion resistance effect, surface of steel coil shall be applied with color coating and baking to attain covering and insulation effect, beautification and extend the service life of steel materials.

Product Features

- Extending service life of products:

Color coating is for protecting steel substrate and for promoting corrosion control effects. Subject to the environment, the different coating combination promotes environmental resisting functions (such as heat resistance, corrosion resistance, humidity resistance, bending resistance, weathering resistance, impact resistance, acid / alkali resistance, chemical resistance and pollution resistance) to offer ultra durability. - Better forming ability:

Coating Layer has good bending ability and in high speed forming, it maintains good forming ability and would not cracking or peel off. The coating could be adjusted to meet for different substrate general use, drawing, deep drawing or lock forming, structural use and other purposes. - Variable colors:

With different glosses and colors, it displays beautiful appearance that allow for new product designs, diversified creative elements and higher living quality.

The smooth and even Protective Film form by coating on coated surface shall be:- formed film with good bonding ability with steel substrate.

- resistance against sunlight, air, moisture, acid rain, grease.

- It shall have the feature of mopping resistance, abrasion resistance and impacting resistance.

Prepainted Sketch {2 coat and 2 bake system}

Frequent Type of Coating

Type of Coating |

Brief Introduction |

| Polyester(PE) | PE is well-adhesive to the substrate and its coated products is formability。The Products are normally used at better environment circumstances. |

| Silicone Modified Polyester(SMP) | The excellent color maintenance and heat resistance properties of Silicone resin could improve the weatherability and modify the heat resistance, chalky, resistance of PE coating. |

| Polyvinylidene Fluoride(PVDF) | PVDF got very strong bonding so it has very good corrosion resistance and color maintenance. Also excellent in heat resistance, UV resistance and chemical resistance. PVDF offer long-term protection function to the substrate and could offer variety of colors and special metallic coating for decoration color steel. |

Application

- Building Materials

Exterior decoration: Roof, Exterior decoration of building, Door, Door panel, Garage door panel, Fast Roll-Up, Fencing wall, Metal window frame, Metal roof tile, Pre-Fabric house, Gutter.

Interior decoration: Wall, Partition, Sandwich panel, Ceiling, Lighting equipment material, Light steel frame, Decorative material.

Equipment structure: Ventilation duct, Floor deck, Light weight form steel, Construction scaffolding.

Furniture: Steel furniture, Curtain slide rail, Slide rail, Wardrobe. - Automobile

Equipment: Interior decoration, Car shed, Car interior lamp cover. - Transportation Machinery & Equipment

Railroad vehicle: Interior decoration board, Ceiling

Equipment: Ship interior decoration, Truck / Reefer car exterior panel, Car body exterior / interior panel.

- Electrical Machinery

Kitchen: shell of refrigerator, Kitchen collecting chest panel, Kitchen ventilator, Dish washer, Dryer, Small appliance

Air Regulator Equipment: Shell of air conditioner, Shell of water heater, Side panel and supporting bracket of solar energy panel, Outer shell of exterior unit of heat pump - Home Appliance / Others: Washing machine, Lighting equipment, Stereo, TV set, Video recorder, Power supply shell, Distribution panel

- Others

Others: Sign board, Black (White) board, Tool kits box, Thunder arrestor cover, Water tower, Acoustic wall, Silo, Stable, Staple house.

Type symbols table of prepainted hot dip galvanized steel

| Spec. | JIS | CNS | ASTM |

| Type of substrate | GI | GI | GI |

| Specification | CGCC | CGCC | CS Type A , B , C |

| FS | |||

| CGCD1~3 | CGCD1~3 | DS/DDS | |

| EDDS | |||

| Grade 33 (Gr.230) | |||

| CGC340 | CGC340 | Grade 37 (Gr.255) | |

| Grade 40 (Gr.275) | |||

| CGC400 | CGC400 | ||

| CGC440 | CGC440 | Grade 50 (Gr.340) | |

| CGC490 | CGC490 | ||

| Grade 55 (Gr.380) | |||

| Grade 60 (Gr.410) | |||

| Grade 70 (Gr.480) | |||

| CGC570 | CGC570 | Grade 80 (Gr.550) |

Type symbols table of prepainted hot dip 55% Al-Zn coated steel

| Spec. | JIS | CNS | ASTM |

| Type of substrate | GL | GL | GL |

| Specification | CGLCC | CGLCC | CS Type A , B , C |

| FS | |||

| CGLCD | CGLCD | DS/DDS | |

| CGLCDD | CGLCDD | EDDS | |

| CGLC340 | CGLC340 | ||

| Grade 33(Gr.230) | |||

| CGLC400 | CGLC400 | Grade 37(Gr.255) | |

| Grade 40(Gr.275) | |||

| CGLC440 | CGLC440 | ||

| CGLC490 | CGLC490 | Grade 50(Gr.340) | |

| Grade 55(Gr.380) | |||

| Grade 60(Gr.410) | |||

| CGLC570 | CGLC570 | ||

| Grade70(Gr.480) | |||

| Grade80(Gr.550) |

Type symbols and mechanical property of prepainted hot dip galvanized steel

| Type Symbol of prepainted hot dip galvanized Steel JIS G3312 |

Min. Yield Point N/mm2 |

Min. Tensile Strength N/mm2 |

Min. Elongation% | Uses | |||

| Nominal Thickness mm (t) | |||||||

| 0.25≤t<0.4 | 0.4≤t<0.6 | 0.6≤t<1.0 | 1.0≤t<1.6 | ||||

| CGCC | --- | --- | --- | --- | --- | --- | Commercial |

| CGCH | --- | --- | --- | --- | --- | --- | Full hard |

| CGCD1 | --- | 270 | --- | 34 | 36 | 37 | Drawing |

| CGC340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | 295 | 400 | 18 | 18 | 18 | 18 | Structural |

| CGC440 | 335 | 440 | 18 | 18 | 18 | 18 | Structural |

| CGC490 | 365 | 490 | 16 | 16 | 16 | 16 | Structural |

| CGC570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Min. Yield Point ksi(MPa) |

Min. Tensile Strength ksi(MPa) |

Min. Elongation% |

Uses | |||

| A653(M) CS TYPE A,B,C | --- | --- | --- | Commercial | |||

| A653(M) FS TYPE A,B | --- | --- | --- | Forming | |||

| A653(M)DDS | --- | --- | --- | Drawing | |||

| A653(M) SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | |||

| A653(M) SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | |||

| A653(M) SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | |||

| A653(M) SS Grade50(340) | 50(340) | 65(450) | 12 | Structural | |||

| A653(M) SS Grade60(410) | 60(410) | 70(480) | 10 | Structural | |||

| A653(M) SS Grade80(550) | 80(550) | 82(570) | --- | Structural | |||

※A653(M) Indicates in Metric System

Type symbols and mechanical property of prepainted hot dip 55% Al-Zn coated steel

| Type Symbol of prepainted hot dip 55% Al-Zn Coated Steel JIS G3322 |

Min. Yield Point N/mm2 | Min. Tensile Strength N/mm2 | Min Elongation % | Uses | |||

| Nominal Thickness mm (t) | |||||||

| 0.25≤t<0.4 | 0.4≤t<0.6 | 0.6≤t<1.0 | 1.0≤t<1.6 | ||||

| CGLCC | (205) | (270) | (20) | (21) | (24) | (24) | Commercial |

| CGLCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGLC400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGLC440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGLC490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGLC570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Min. Yield Point ksi(MPa) |

Min. Tensile Strength ksi(MPa) |

Min. Elongation % | Uses |

| A792(M) CS TYPE A,B,C | --- | --- | --- | Commercial |

| A792(M) FS | --- | --- | --- | Forming |

| A792(M) DS | --- | --- | --- | Drawing |

| A792(M) SS Grade33(230) | 33(230) | 45(310) | 20 | Structural |

| A792(M) SS Grade37(255) | 37(255) | 52(360) | 18 | Structural |

| A792(M) SS Grade40(275) | 40(275) | 55(380) | 16 | Structural |

| A792(M) SS Grade50(340) | 50(340) | 65(450) | 12 | Structural |

| A792(M) SS Grade60(410) | 60(410) | 70(450) | 10 | Structural |

| A792(M) SS Grade80(550) | 80(550) | 82(570) | --- | Structural |

※A792(M) Indicates in Metric System